Micro Surfacing

Micro-Surfacing

Micro Surfacing

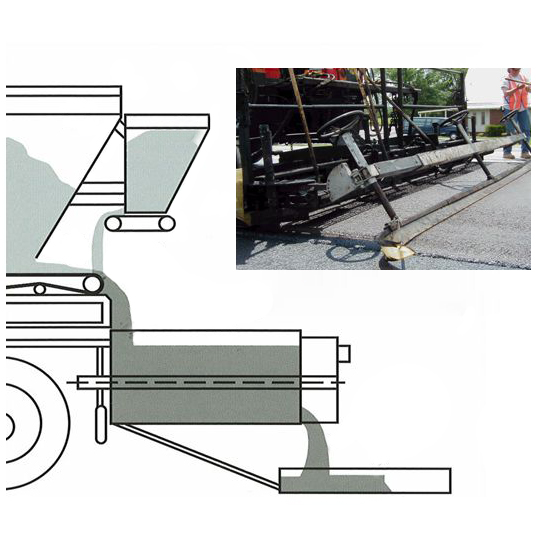

Applying a mixture of aggregates, water, Bitumen Emulsion (CSS), filler (usually cement) and some additives based on the place condition. This operation requires a special paving machine (similar to Slurry Seal machine) that can be assembled on site.

Micro-Surfacing application and facts:

1- There is no need to roll with any kind of road roller.

2- We can find out the end of the breaking process when brown color turns to black color.

3- It is so recommended for places with high traffic like big cities, airports and high ways.

4- It is very resistant to fatigue and attrition.

5- It creates a good color contrast.

6- It can be used as a colored coat by adding some additives (used for bike lanes).

7- When using Micro-surfacing on bridge surface, there is no need to remove the surface due to its light weight and low thickness.

8- It can be used on both asphalt and concrete surfaces.

9- Its average life time is 5 to 7 years.

10- Micro-surfacing seals cracks and voids and completely makes the surface smooth.

Micro-surfacing applications and facts:

11- It is very economical.

12- Due to its low thickness, there is no need to bring up the position of guard rails, curbstones or shoulder of the road.

13- Use of thermal energy, fuel and aggregates are notably less than similar approaches in the whole paving process.

14- Micro-surfacing is very proper for environment.

15- Since there is no need to roll with road rollers, Micro-surfacing surface may crack or it may cause reflective cracks in places with big cracks or places where two lanes reach together or places where two roads intersect. So, we should note to seal it.

16- The aggregates’ sizes must be proper for the Micro-surfacing, usually between 3 to 12mm.

17- The surface must be clean and dust and oil must be removed.

18- If there are transverse, longitudinal, block cracks or vehicle tire deep grooves, they must be sealed first (by Bitumen Emulsion CSS or CRS) and then, it is prepared for Micro-Surfacing.