What Is Bitumen

Crude Oil and Hydrocarbon Materials

Millions of years ago, algae and plants lived in shallow seas. After dying and sinking to the seafloor, the organic material mixed with other sediments and was buried. Over millions of years under high pressure and high temperature, the remains of these organisms transformed into what we know today as fossil fuels. Coal, natural gas, and petroleum are all fossil fuels that formed under similar conditions. Today, petroleum is found in vast underground reservoirs where ancient seas were located. Petroleum reservoirs can be found beneath land or the ocean floor. Their crude oil is extracted with giant drilling machines. Crude oil is usually black or dark brown, but can also be yellowish, reddish, tan, or even greenish. Variations in color indicate the distinct chemical compositions of different supplies of crude oil. Petroleum that has few metals or sulfur, for instance, tends to be lighter (sometimes nearly clear). Petroleum is used to make gasoline, an important product in our everyday lives. It is also processed and part of thousands of different items, including tires, refrigerators, life jackets, and anesthetics. When petroleum products such as gasoline are burned for energy, they release toxic gases and high amounts of carbon dioxide, a greenhouse gas. Carbon helps regulate the Earth’s atmospheric temperature, and adding to the natural balance by burning fossil fuels adversely affects our climate. There are huge quantities of petroleum found under Earth’s surface and in tar pits that bubble to the surface. Petroleum even exists far below the deepest wells that are developed to extract it. However, petroleum, like coal and natural gas, is a non-renewable source of energy. It took millions of years for it to form, and when it is extracted and consumed, there is no way for us to replace it. Oil supplies will run out. Eventually, the world will reach “peak oil,” or its highest production level. Some experts predict peak oil could come as soon as 2050. Finding alternatives to petroleum is crucial to global energy use, and is the focus of many industries.

Petroleum Reservoirs

Petroleum is found in underground pockets called reservoirs. Deep beneath the Earth, pressure is extremely high. Petroleum slowly seeps out toward the surface, where there is lower pressure. It continues this movement from high to low pressure until it encounters a layer of rock that is impermeable. The petroleum then collects in reservoirs, which can be several hundred meters below the surface of the Earth. Petroleum can be contained by structural traps, which are formed when massive layers of rock are bent or faulted (broken) from the Earth’s shifting landmasses. Oil can also be contained by stratigraphic traps. Different strata, or layers of rock, can have different amounts of porosity. Crude oil migrates easily through a layer of sandstone, for instance, but would be trapped beneath a layer of shale. Geologists, chemists, and engineers look for geological structures that typically trap petroleum. They use a process called “seismic reflection” to locate underground rock structures that might have trapped crude oil. During the process, a small explosion is set off. Sound waves travel underground, bounce off of the different types of rock, and return to the surface. Sensors on the ground interpret the returning sound waves to determine the underground geological layout and possibility of a petroleum reservoir. A land area with an abundance of oil wells extracting petroleum (crude oil) from below ground is called oil field. Because the oil reservoirs typically extend over a large area, possibly several hundred kilometers across, full exploitation entails multiple wells scattered across the area. In addition, there may be exploratory wells probing the edges, pipelines to transport the oil elsewhere, and support facilities. The amount of petroleum in a reservoir is measured in barrels or tons. An oil barrel is about 42 gallons. This measurement is usually used by oil producers in the United States. Oil producers in Europe and Asia tend to measure in metric tons. There are about 6 to 8 barrels of oil in a metric ton. The conversion is imprecise because different varieties of oil weigh different amounts, depending on the amount of impurities.

Crude oil is frequently found in reservoirs along with natural gas. In the past, natural gas was either burned or allowed to escape into the atmosphere. Now, technology has been developed to capture the natural gas and either reinject it into the well or compress it into liquid natural gas (LNG). LNG is easily transportable and has versatile uses. Crude or unprocessed oil is not very useful, and it does not have much use in the way it comes out of the ground. Although, sweet crude oil (low in viscosity and low sulfur content) can be used as a diesel fuel in steam-powered vessels, gases and other lighter solutions but usually accumulates in the fuel tank and leads to an explosion. Unless otherwise stated, crude oil is to be refined to produce other products such as plastics, foams and etc.

The refinery's products are light to heavy, respectively:

Liquid Gas (LPG)

Gasoline

Naphtha is a slice of gasoline and kerosene, and its characteristics are a combination of these two.

Kerosene and Jet Fuels related to it

Gasoline (Liquefied Petroleum Gas) and, in general, Diesel Fuels

The petrol is known as Mazut (Fuel Oil or Black Oil

Petroleum Oils

Paraffin Wax

Bitumen

Petroleum Coke

Sulfur

Chemistry

Crude oil is composed of hydrocarbons, which are mainly hydrogen (about 13% by weight) and carbon (about 85%). Other elements such as nitrogen (about 0.5%), sulfur (0.5%), oxygen (1%), and metals such as iron, nickel, and copper (less than 0.1%) can also be mixed in with the hydrocarbons in small amounts. The way molecules are organized in the hydrocarbon is a result of the original composition of the algae, plants, or plankton from millions of years ago. The amount of heat and pressure the plants were exposed to also contributes to variations that are found in hydrocarbons and crude oil. Due to this variation, crude oil that is pumped from the ground can consist of hundreds of different petroleum compounds. Light oils can contain up to 97% hydrocarbons, while heavier oils and bitumen might contain only 50% hydrocarbons and larger quantities of other elements. It is almost always necessary to refine crude oil in order to make useful products. Sometimes all forms of oil are also called hydrocarbon. Crude oil, tar, bitumen and condensate are all petroleum hydrocarbons. The most important characteristics of crude oil that affect the market price are its sulfur content and gravity. Low sulfur content of crude oil is particularly preferred. Petroleum includes crude oil, natural gas, and heavy oil. Petroleum refineries convert crude oils and other input streams into dozens of refined (co)products. Two properties are especially useful for quickly classifying and comparing crude oils: API gravity (a measure of density) and sulfur content. Sulfur is naturally present as an impurity in fossil fuels. The removal of organosulfur compounds from crude oil is an important aspect of all countries to reduce air pollution.

What Is “Sweet” Crude Oil?

Crude oil with low sulfur content is classified as “sweet;” crude oil with a higher sulfur content is classified as “sour.” Sulfur content is considered an undesirable characteristic with respect to both processing and end-product quality. Therefore, sweet crude is typically more desirable and valuable than sour crude.

Natural Bitumen (Asphalt)

Crude can be classified as “light” or “heavy,” a characteristic which refers to the oil’s relative density based on the American Petroleum Institute (API) Gravity. This measurement reflects how light or heavy a crude oil is compared to water. If an oil’s API Gravity is greater than 10, it is lighter than water and will float on it. If an oil’s API Gravity is less than 10, it is heavier than water and will sink. Lighter crude is easier and less expensive to produce. It has a higher percentage of light hydrocarbons that can be recovered with simple distillation at a refinery. Heavy crude can’t be produced, transported, and refined by conventional methods because it has high concentrations of sulfur and several metals, particularly nickel and vanadium. Heavy crude has density approaching or even exceeding that of water. Heavy crude oil is also known as “tar sands” because of its high bitumen content. With simple distillation, dense, heavier crude oil produces a greater share of lower-valued products. Heavy crude requires extra refining to produce more valuable and in-demand products.

Asphalt, Bitumen, Tar, Pitch

Asphalt

Asphalt also known as bitumen is a sticky, black, and highly viscous liquid or semi-solid form of petroleum. It is a refined product. The primary use (70%) of asphalt is in road construction, where it is used as the glue or binder mixed with aggregate particles to create asphalt concrete. Its other main uses are for bituminous waterproofing products, including production of roofing felt and for sealing flat roofs. The terms "asphalt" and "bitumen" are often used interchangeably to mean both natural and manufactured forms of the substance. In American English, "asphalt" (or "asphalt cement") is commonly used for a refined residue from the distillation process of selected crude oils. Outside the United States, the product is often called "bitumen", and geologists worldwide often prefer the term for the naturally occurring variety. Naturally occurring asphalt is sometimes specified by the term "crude bitumen". Its viscosity is similar to that of cold molasses while the material obtained from the fractional distillation of crude oil boiling at 525 °C (977 °F) is sometimes referred to as "refined bitumen".

Bitumen

Bitumen is a dense, highly viscous, petroleum-based hydrocarbon that is mainly used in moisture insulation and asphalt manufacturing industries. Generally, it is obtained as a residue of the distillation of crude oil (refined bitumen). Such bitumen is called naphtha bitumen or distillation bitumen. Bitumen has a variety of types, each of which has a special application. With the advancement of science and technology bituminous applications became very diverse and widely used in various industries and for various uses including road construction, coating, flooring, roofing, underground metal protective coatings, sealing of reservoirs, canals, bridges, stabilization of sand, staining and etc. Today, more than 250 different applications for bitumen in agriculture, construction industry, road construction and many other industries are considered. In the United States and some areas bitumen is often called asphalt. Bitumen is solid at ambient temperature but as the temperature rises, it becomes paste-like and then it becomes fluid. Important application of bitumen is due to the two

important properties of this substance:

1- Impermeability against water

2- Adhesion

Tar, Pitch

Bitumen is also frequently called tar or pitch—though, properly speaking, tar is a byproduct of the carbonization of coal and pitch is actually obtained from the distillation of coal tar. Bitumen is defined by the U.S. Geological Survey as an extra-heavy oil with an API gravity less than 10° and a viscosity greater than 10,000 centipoises.

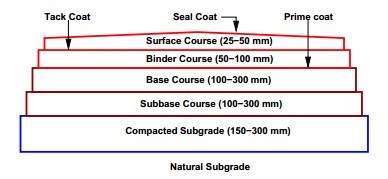

Bitumen as a Bonding Agent

The major bitumen produced in Iran and the world is used in road construction sector. In road construction, bitumen is used as a bonding agent in asphalt and in the construction industry, it is ranked second with insulation (waterproofing). Estimations show that the annual amount of bitumen in the world is about 102 million tons. About 85% of this bitumen is used in the road construction industry and the 60/70 bitumen is used the most. More than 10% of the bitumen produced in the world is used in the building industry and as waterproofing and the rest is used in sealing, insulating, pipes and etc.

Direct Bitumen Extraction of Crude Oil

Distillation is a major process in petroleum refining. Petroleum bitumen is a product of two stages of distillation of crude oil in distillation column. The bitumen is a residual or heavy residue of distillation of crude oil. The amount of bitumen crude oil varies from zero to more than half of that. In addition, bitumen from different sources can be very different. Therefore, bitumen refineries should carefully select their crude oil to ensure their bitumen quality. Direct extraction from Crude Oil Distillation is a major process for crude oil refining. The first stage of distillation is under atmospheric pressure, and typically consists of heating the crude oil to a temperature of about 650 to 800 degrees Fahrenheit, and then injects it into a separation column. In this way, the lighter sections are referred to as high-grade tops and asphalt residues, called atmospheric substitutes. This is the first step in the entire filtration process. Many crude oils contain high percentages of high-creep cuts that cannot be distilled into an atmospheric distillation unit. A separation tower that works in vacuum conditions is used to separate these slices and to provide bitumen with the desired characteristics. The process of producing asphalt by vacuum distillation, except for penetration, has a very small effect on other properties of bitumen. The origin of crude oil also has a significant effect on the physical properties of bitumen.

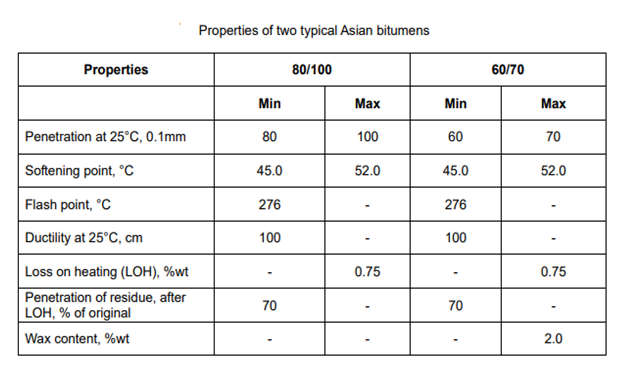

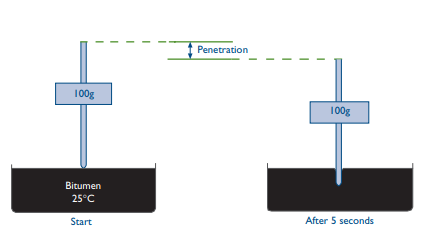

PERFORMANCE GRADED BITUMEN SPECIFICATIONS

Penetration graded specifications for bituminous binders focus on the low service temperature (25°C) properties of the binder. The penetration test is empirical; it does not involve the measurement of any fundamental engineering parameters. Recognizing the limitations of empirical testing, the US Strategic Highway Research Program (SHRP) sponsored a major research effort to develop performance based tests and specifications for binders and hot mix asphalt mixes. This resulted in the development of the Superpave Performance Grading (PG) system has had significant impact on binder specifications outside the US. Most Asian bitumens are specified by the Penetration Test at 25°C. The bitumen samples are subjected under a 100 g load for a duration of 5 s at 25°C. Designation used is according to the penetration range i.e. 40/60 pen bitumen has a penetration range between 40 and 60 deci millimetres (dmm). In 1918, Scientists introduced penetration grading system by developing various penetration grades suited to different climatic conditions and applications. Penetration grading was developed to characterize the consistency of bitumen. Further information can be obtained from AASHTO M 20-70 (2004) and ASTM D946-82 (2005).

Tar, Pitch

Bitumen is also frequently called tar or pitch—though, properly speaking, tar is a byproduct of the carbonization of coal and pitch is actually obtained from the distillation of coal tar. Bitumen is defined by the U.S. Geological Survey as an extra-heavy oil with an API gravity less than 10° and a viscosity greater than 10,000 centipoises.

Most Commonly Used Bitumen Specifications

Cutback Bitumens

Normal practice is to heat bitumen to reduce its viscosity. In some situations, preference is given to use liquid binders such as cutback bitumen. In cutback bitumen suitable solvent is used to lower the viscosity of the bitumen. From the environmental point of view also cutback bitumen is preferred. The solvent from the bituminous material will evaporate and the bitumen will bind the aggregate. Cutback bitumen is used for cold weather bituminous road construction and maintenance. The distillates used for preparation of cutback bitumen are naphtha, kerosene, diesel oil, and furnace oil. There are different types of cutback bitumen like rapid curing (RC), medium curing (MC), and slow curing (SC). RC is recommended for surface dressing and patchwork. MC is recommended for premix with less quantity of fine aggregates. SC is used for premix with appreciable quantity of fine aggregates.

Bitumen Emulsion

Bitumen emulsion is a liquid product in which bitumen is suspended in a finely divided condition in an aqueous medium and stabilized by suitable material. Normally cationic type emulsions are used in India. The bitumen content in the emulsion is around 30% to 70% and the remaining is water. When the emulsion is applied on the road it breaks down resulting in release of water and the mix starts to set. The time of setting depends upon the grade of bitumen. Three types of bituminous emulsions are available, which are Rapid setting (RS), Medium setting (MS), and Slow setting (SC). Bitumen emulsions are ideal binders for hill road construction. Where heating of bitumen or aggregates are difficult. Rapid setting emulsions are used for surface dressing work. Medium setting emulsions are preferred for premix jobs and patch repairs work. Slow setting emulsions are preferred in rainy season.

Bituminous Primers

In bituminous primer the distillate is absorbed by the road surface on which it is spread. The absorption therefore depends on the porosity of the surface. Bitumen primers are useful on the stabilized surfaces and water bound macadam base courses. Bituminous primers are generally prepared on road sites by mixing penetration bitumen with petroleum distillate.

Modified Bitumen

Certain additives or blend of additives called as bitumen modifiers can improve properties of Bitumen and bituminous mixes. Bitumen treated with these modifiers is known as modified bitumen. Polymer modified bitumen (PMB)/ crumb rubber modified bitumen (CRMB) should be used only in wearing course depending upon the requirements of extreme climatic variations. It must be noted that the performance of PMB and CRMB is dependent on strict control on temperature during construction. The advantages of using modified bitumen are as follows:

- Lower susceptibility to daily and seasonal temperature variations

- Higher resistance to deformation at high pavement temperature

- Better age resistance properties

- Higher fatigue life for mixes

- Better adhesion between aggregates and binder

- Prevention of cracking and reflective cracking

Standards and Grading Systems/ Standardizing Bodies

In different regions and countries, different Standards and Grading systems are used for determining the quality of petroleum bituminous Binders. The most recognized

standards for petroleum bitumen are published by:

- European Committee for Standardization (CEN)

- Deutsche Industrie Norm (DIN EN)

- Association Française de Normalisation (AFNOR – NF EN)

- BSI Standards - the UK's National Standards Body (NSB - BS EN)

- American Society for Testing and Materials (ASTM)

- American Association of State Highway and Transportation Officials (AASHTO)

- South African Standard Organization (SABS)

- Standards Australia (AS)

Standards for Petroleum Bitumen Grades

- ASTM D 946 and AASHTO M 20 (Penetration @ 25°C)

- ASTM D 3381 and AASHTO M 226 (Viscosity @ 60°C)

- ASTM D 6373 and AASHTO M 320 (PG-Graded Binder)

- EN 12591 (Penetration @ 25°C) → NF EN; BS EN; DIN EN; etc.

- AS 2008 (Viscosity @ 60°C)

- SABS 307 (Penetration @ 25°C; Viscosity @ 60°C after RTFOT)

- IS 73 (India) changed in 2006 from PEN grades to VG Grades (based on Viscosity @ 60°C); however, CRMB modified bitumen is still graded based on penetration.

Bitumen Emulsion (Anionic; Cationic)

- USA Anionic Emulsions: ASTM D 977 and AASHTO M 140

- USA Cationic Emulsions: ASTM D 2397 and AASHTO M 208; Polymer Modified Cationic Emulsion: AASHTO M 316

- Europe: Harmonized Framework Standard EN 13808 for Cationic Unmodified and Polymer Modified Emulsions; many different nationals

Polymer Modified Bitumen

- ASTM D 5976; ASTM D 5840; ASTM D 5841 (based on polymer type; now outdated and not used in the USA, but still used in some developing countries)

- ASTM 6373 and AASHTO M 320 (PG-Graded Binder; applicable to Unmodified and Polymer Modified Bitumen)

- EN 14023 (Framework Standard for Polymer Modified Binder)

- AUSTROADS Framework Specifications (Australia)

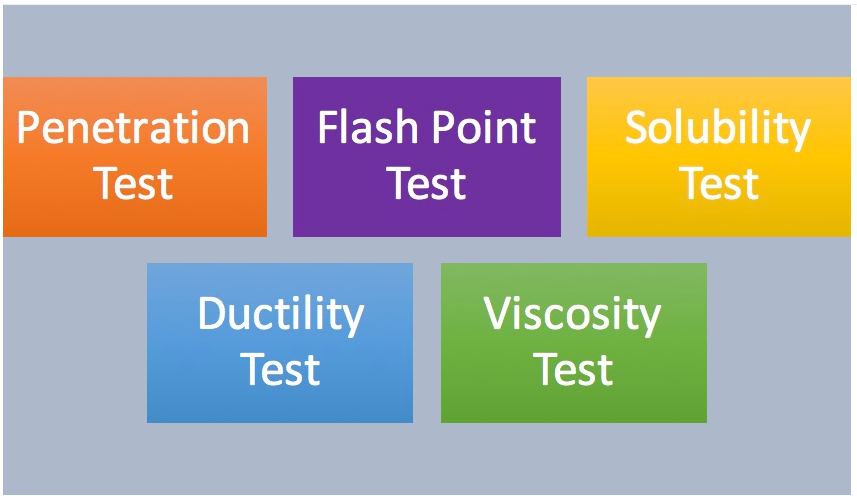

Tests Applied on Bitumen in Roads for Quality Construction

Penetration Grade/ Test

Penetration Grade bitumen is specified by the penetration and softening point test. Designation is by penetration range only. The penetration grade bitumen has a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. Penetration Test measures the hardness or softness of bitumen by measuring the depth in tenths of a millimeter to which a standard loaded needle will penetrate vertically at 25C for 5 seconds. The penetration of a bituminous material is the distance in tenths of a mm, that a standard needle would penetrate vertically, into a sample of the material under standard conditions of temperature, load and time.

Viscosity Grade Bitumen (Asphalt)

Viscosity Its defined as fluid property of the material as resistance to flow. Viscosity Grade Bitumen is a standard grade Bitumen usually used as a Paving Grade Bitumen suitable for road construction and for the production of asphalt pavements with superior properties Viscosity Test of Bitumen denotes the fluid property of bituminous material and it is a measure of resistance to flow. At the application temperature, this characteristic greatly influences the strength of resulting paving mixes. Low or high viscosity during compaction or mixing has been observed to result in lower stability values. At high viscosity, it resists the compactive effort and thereby resulting mix is heterogeneous, hence low stability values. And at low viscosity instead of providing a uniform film over aggregates, it will lubricate the aggregate particles. In viscosity test, the viscosity of bitumen (asphalt) is measured at 60 °C (140 °F) after the roll on thin film oven test.

• Saybolt Furol viscosity test is used to determine viscosity of liquid bitumen. In this test, time in seconds is noted for 60 ml of the liquid bitumen at specified temperature to flow through an orifice of a specific size.

• The Basic Kinematic viscosity test measures the time it takes for a fixed volume of asphalt binder to flow through a capillary viscometer under closely controlled conditions of head and temperature (ASTM, 2001).

Significance of Viscosity Test:

• Too viscous bitumen would result in inadequate and non-uniform coating of the aggregates.

• Very low viscosity would again result in inadequate coating as the bitumen will tend to bleed.

• Therefore, viscosity at 135oC is a true reflection of the quality of bond that is likely to be formed with the aggregate.

Penetration vs Viscosity

Penetration based specification has its focus primarily on the low service temperature at 25°C. Whereas, viscosity graded specification controls the temperature susceptibility of a bitumen by means of viscosity at the critical performance temperature of 60°C. The penetration test is an empirical one and does not measure a fundamental engineering parameter such as viscosity. It is also impossible to determine the temperature susceptibility of a bitumen based on a single test conducted at 25°C. By contrast, in the viscosity grading system, the bitumen is tested at three different temperatures i.e. viscosity at 60°C, 135°C, and penetration at 25°C.

Fire (Flash) Point Test

At high temperatures depending upon the grades of bitumen materials leave out volatiles. And these volatiles catch fire which is very hazardous and therefore it is essential to qualify this temperature for each bitumen grade. The fire point is defined as the lowest temperature under specified test conditions at which the bituminous material gets ignited and burns. In other words, it is defined as the critical temperature of asphalt (°C) when the mixture of air and flammable gas generated when asphalt is heated touches a flame and keeps burning for 5s. Asphalt/bitumen is similar to the organic matter in carbonaceous meteorites. They are from oil; the temperature should of 50 to 150 °C (120 to 300 °F).

Testing of Bitumen Weight Loss on Heating

When the bitumen is heated it loses the volatility and gets hardened. components. This characteristic is also important properties of bitumen. About 50gm of the sample is weighed and heated to a temperature of 1630C for 5 hours in a specified oven designed for this test. The sample specimen is weighed again after the heating period and loss in weight is expressed as percentage by weight of the original sample. Bitumen used in pavement mixes should not indicate more than 1% loss in weight, but for bitumen having penetration values 150-200 up to 2% loss in weight is allowed.

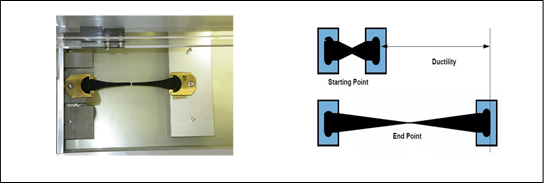

Ductility Test

The adhesive property of bitumen and its ability to stretch is calculated by the ductility test. Binder material having insufficient ductility gets cracked when subjected to repeated traffic loads and it results in rain water getting through and ruining the road. Since roads involve vehicular traffic and heavy loads, they need to be built to last for a while. If the road surface can 'stretch' a little under heavy loads, it is bound to last for a while without repairs. Bitumen is actually the liquid binder that holds asphalt together. Asphalt is produced by mixing an aggregate of materials such as sand, gravel and crushed stones with bitumen into a composite mix. It is necessary therefore, that the binder (bitumen) forms a thin ductile film around aggregates so that physical interlocking of the aggregates is improved. Binder material having insufficient ductility gets cracked when subjected to repeated traffic loads and it results in rain water getting through and ruining the road. A standard compressed block of the aggregate is stretched at a specified speed and temperature until it breaks; the ductility is measured by the distance in centimeters to which the material stretches before breaking.

Importance of Ductility: The ductility of a bitumen specimen tells us about:

i)- Tensile strength of bitumen

ii)- Grade of sample (ductility grade

Solubility Test for Bitumen and Bituminous Binders

Asphalt consists primarily of bitumen, which are high-molecular-weight hydrocarbons soluble in carbon disulfide. The bitumen content of a bituminous material is measured by means of its solubility in carbon disulfide. Procedure for Solubility test on Bitumen: In the standard test for bitumen content (ASTM D4), a small sample of about 2 g of the asphalt is dissolved in 100 ml of carbon disulfide and the solution is filtered through a filtering mat in a filtering crucible. The material retained on the filter is then dried and weighed, and used to calculate the bitumen content as a percentage of the weight of the original asphalt. The solubility test is used to detect contamination in asphalt cement. The degree of purity is: (sample bitumen weight) ÷ [(impurity weight) – (bitumen weight)]

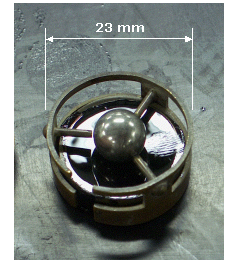

Softening Point

The softening point is defined as the temperature at which a bitumen sample can no longer support the weight of a 3.5-g steel ball. Although it is commonly used in Europe, it is mostly used for roofing asphalts in the U.S. Uses of Softening Point: The determination of softening point helps to know the temperature up to which a bituminous binder should be heated for various road use applications.

Ring and ball test is used to determine the softening point of bitumen, asphalt and coal tar. This test consists of two horizontal disks of bitumen, cast in shouldered brass rings are heated at a controlled rate in a liquid bath while each supports a steel ball. The softening point is reported as the mean of the temperatures at which the two disks soften enough to allow each ball, enveloped in bitumen, to fall a distance of 25 mm (1.0 inch) (AASHTO, 2000).

Types of Petroleum (Refined) Bitumen

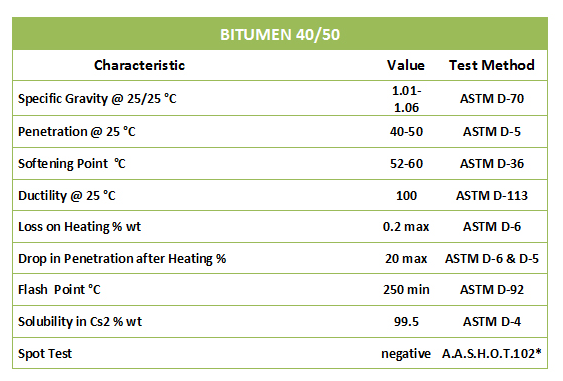

Bitumen is available in a variety of grades. Specifications vary to meet the needs of the consuming industries and are based on a series of physical tests that define the safety, solubility, physical properties and durability of bitumen. The physical properties are designed to define performance characteristics that are required under the climatic and loading conditions that the bitumen will experience in service. Bitumen is graded according to standardized testing methods. Penetration Grade Bitumen is mainly used in road construction, surfacing and some industrial applications.

Product Description

Penetration Grade Bitumen 40/50.

USES: Bitumen Grade 40/50 is commonly used to manufacture asphalt mixes, bitumen emulsion, cut-back bitumen and modified bitumen.

RESTRICTIONS: This product must not be used in applications other than the above without first seeking the advice of the supplier.

PACKAGING: Steel Drum / 1Mt Jumbo bag/ Bulk

Product Description

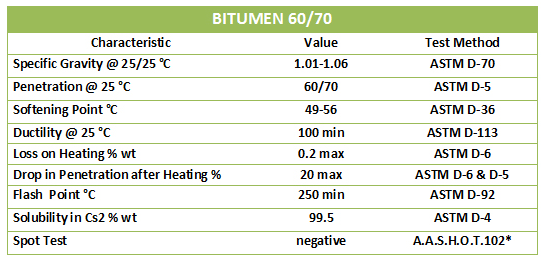

Penetration Grade Bitumen 60/70.

Uses: Bitumen Grade 60/70 is commonly used to manufacture asphalt mixes, bitumen emulsion, cut-back bitumen and modified bitumen.

RESTRICTIONS: This product must not be used in applications other than the above without first seeking the advice of the supplier.

Packaging: Steel Drum / 1Mt Jumbo bag/ Bulk

Product Description

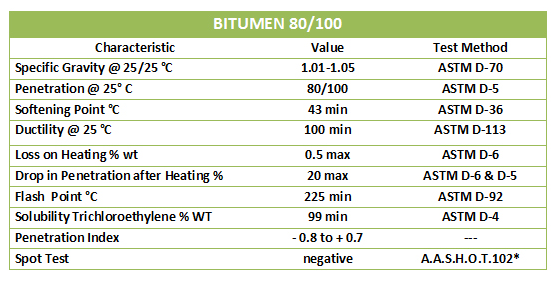

Penetration Grade Bitumen 80/100.

Uses: Bitumen Grade 80/100 is commonly used to manufacture asphalt mixes, bitumen emulsion, cut-back bitumen and modified bitumen.

Packaging: Steel Drum / 1Mt Jumbo bag/ Bulk

Bitumen Use

Bitumen and bituminous products are often used for their adhesive and waterproofing properties and are therefore sometimes referred to as binders. Because asphalt is impervious to water as well as many other substances, it has been beneficially used by humans for thousands of years. Most refined bitumen is used in the construction industry. Mainly, it serves its use in paving and roofing applications. 85% of all bitumen is used as a binder in asphalt for roads, runways, parking lots, and foot paths. Gravel and crushed rock are mixed with thick bitumen, holding it together and it is then applied to roadways. 10% of the bitumen used worldwide is used in the roofing industry as its waterproofing qualities help make roofs function well. 5% of bitumen is used for sealing and insulating purposes in various building materials such as carpet tile backing and paint. In addition to these main uses, bitumen also has many minor uses. Other examples are soundproofing, explosives, mildew protection, a binder in briquettes, a backing to mirrors, shoe soles, fence post coating and soil stabilization. In summary, all bitumen is not the same. Each bitumen is designed and produced for a specific end-use application. Beyond physical characteristics, conditions such as application temperature and other application-related factors should be considered when trying to understand and evaluate exposure potential

Applications of Bitumen:

- • Road Construction.

- • Hydraulics & erosion control Catchment areas, basins.

- • Dam grouting,

- • Dam linings,

- • Embankment protection

- • Dam linings,

- • Embankment protection

- • Ditch linings, Reservoir linings

- • Reservoir linings

- • Jetties, Dyke protection

- • Dyke protection

- • Swimming pools

- • Waste ponds

- • Water barriers

- • Mattresses for levee & bank protection

- • Membrane linings,

- • Waterproofing

- • Revetments

- • Sand dune stabilization,

- • Drainage gutters,

- • Backed felts

Two Most Commonly Used Materials Derived from Petroleum (Refined) Bitumen: What is Bitumen Emulsion?

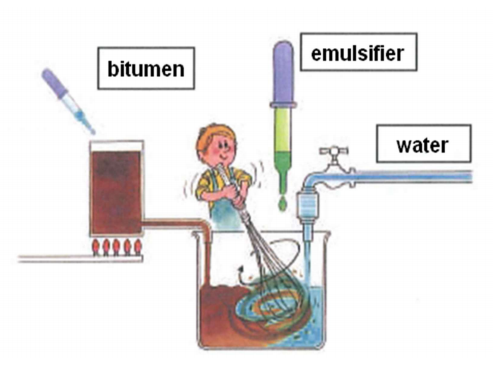

In summary, A mixture of two normally immiscible components (bitumen and water) and an emulsifying agent (usually a surfactant). Bitumen Emulsions are utilized in paving, roofing and waterproofing operations. These materials are called EMULSIFIED ASPHALTS in North America.

In summary, A mixture of two normally immiscible components (bitumen and water) and an emulsifying agent (usually a surfactant). Bitumen Emulsions are utilized in paving, roofing and waterproofing operations. These materials are called EMULSIFIED ASPHALTS in North America.

Definition:

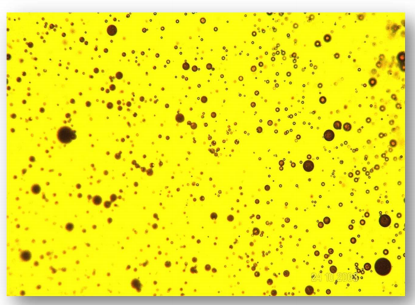

Bitumen Emulsions are fine dispersions of bitumen droplets in water, primarily of straight-run bitumens, although cutback bitumens and modified bitumens can also be used. The bitumen content can range from 30% to 70% by weight. Bitumen emulsions, usually having a relatively low average (particle size particle size of from 2 to 8 microns), can be continuously and speedily prepared by a process comprising feeding emulsion components into the first of at least two static mixers, arranged in series. The product is passed from the first mixer to the second mixer maintained at a temperature lower than that prevailing in the first mixer and below the boiling point of water. The final emulsion product is obtained from the outlet of the second mixer. Bitumen Emulsions are manufactured using high-speed shearing devices, such as colloid mills. Well designed and maintained colloid mills, in conjunction with good emulsifiers, make fine stable emulsions. Other specialist additives can also be used to adjust for changes in bitumen quality or to adjust the break/storage time. To reduce settlement and avoid sedimentation (non-redispersible) correct handling and storage are of major importance.

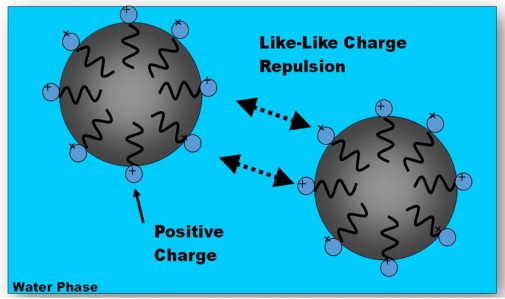

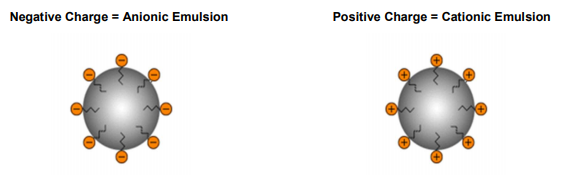

The emulsifier adds a charge to the bitumen droplets and this keeps the particles separated and suspended in the water. They can be anionic, cationic or non-ionic depending on the emulsifier (surfactant) used.

Bitumen emulsions are divided into three categories:

- • Anionic with negatively charged globules

- • Cationic with positively charged globules

- • Non-ionic with neutral globules.

In Iran, the more common variety is Cationic due to having a predominately negatively charged aggregate in the field. Most important is that Cationic and Anionic emulsions should never be mixed to avoid coagulation, cleaning cost and/or cross contamination.

Anionic Emulsions VS Cationic Emulsions

Bitumen emulsions consist of particles of bitumen dispersed in water by using emulsifying agent. When the emulsion breaks, it represents a change from a liquid to a coherent film with bitumen particles coagulating together. The sign of breaking is the change of color from brown to black as the color of emulsion and bitumen is brown and black respectively. There are in common two broad types of emulsions, namely anionic emulsions and cationic emulsions. The breaking of anionic emulsions is dependent on the evaporation of water from bitumen emulsion. As such, it poses difficulty in wet weather condition. However, for cationic emulsions, instead of relying on the evaporation of water the breaking is achieved by chemical coagulation. Hence, cationic emulsions are particularly useful in wet weather conditions.

Types of Bitumen (Bituminous) Emulsions

When the emulsion is applied on the road it breaks down resulting in release of water and the mix starts to set. The time of setting depends upon the grade of bitumen. Three types of bituminous emulsions are available, which are Rapid setting (RS), Medium setting (MS), and Slow setting (SC). Bitumen Emulsions are ideal binders for hill road construction. Where heating of bitumen or aggregates are difficult. Rapid setting emulsions are used for surface dressing work. Medium setting emulsions are preferred for premix jobs and patch repairs work. Slow setting emulsions are preferred in rainy season.

The Benefits of Bitumen (Bituminous) Emulsion

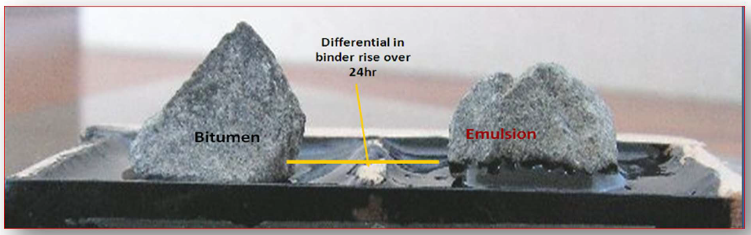

Good cohesion/adhesion (ability to stick to) with aggregate due to the:

• opposite charge of the bitumen to the aggregate

• greater surface coverage of the aggregate resultant from rise of the binder up the aggregate and the initial water content of the emulsion which then evaporates. This is commonly referred to as Binder Rise or Binder Creep.

• Able to be applied in cooler conditions, which extends the sealing season.

• Utilized at lower temperature so no/less chance of sustaining serious burns

• No fuming

Application’s for Bitumen Emulsion

There are many different types of Bitumen Emulsion’s which can be applied for a variety of uses including:

- • Light, medium & heavy traffic

- o maintenance

- o spray sealing - seals

- o spray sealing - primer seals

- o spray sealing - primes

- • Asphalt Tack Coat

- • Dust Suppression

- • Unsealed Road Binding

- • Pre-coating of aggregate

- • Pre-coating of aggregate

- • Crack Sealing

- • Ingredient in the production of cold paving products e.g. Micro Surfacing & Cold Mix Asphalt

Environmental Considerations

Particular care is required when using Bitumen Emulsions when there is a likelihood of rain before the emulsion breaks and the seal is cured. This is especially important when they are used in primer seals or primes. Environmental management plans should include special provisions to manage the risk of their use in such circumstances.

Types

There are 2 Emulsion Types:

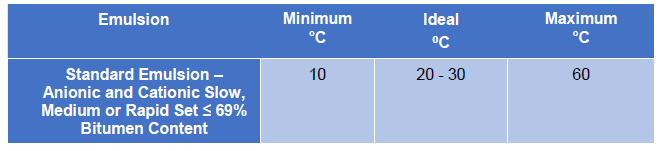

• Standard Emulsions

• High Binder Content Emulsion (HBCE) / Polymer Modified Emulsion (PME) Standard Emulsions are applied at ambient temperatures; it is always advised to avoid direct contact with skin and to have adequate ventilation. Follow the advice in the relevant product Safety Data Sheet. High Binder Content Emulsions (HBCE) / Polymer Modified Emulsions (PME) are handled at temperatures between 80⁰C to 95°C, still significantly lower than straight or polymer modified bitumen products, but at these temperatures, serious burns can occur so the same precautions applied to hot binders should be adopted for these emulsions.

Safety

The length that emulsions can be stored varies according to the emulsion type and components used. For example, rapid-set emulsion has a shorter shelf life than a slow-set emulsion. You should seek advice from your emulsion supplier on the shelf life of their products. Sedimentation and sieve tests are good indicators of an emulsion’s potential storage life. During long-term storage, sedimentation of the bitumen droplets occurs due to the higher density of the bitumen versus water. Regular circulation will help increase the shelf (storage) life of the emulsion but care must be taken not over circulating which can shear the emulsion and causes residue build up. Emulsions may increase in viscosity (thickness) over time and warming the emulsion prior to use will reduce the viscosity.

Storage life

Bituminous Emulsions are the safest form of Bitumen products as they are handled at ambient temperatures which eliminate any chance of burns which can occur with hot applied binders. While Standard Emulsions are applied at ambient temperatures, it is always advised to avoid direct contact with skin and to have adequate ventilation.

Recommended storage temperatures

Emulsions are sensitive to extremes of temperature. It is best to keep them within a temperature range as recommended by the manufacturer. The table below gives a guide to the minimum and maximum storage temperatures for Standard Emulsion types.

What is Bitumen Cutback?

Bitumen is cutback by adding controlled amounts of petroleum distillates such as kerosene. This is done to reduce the viscosity of the bitumen temporarily so it can penetrate pavements more effectively or to allow spraying at temperatures that are too cold for successful sprayed sealing with neat bitumen. The materials used to cutback bitumen will evaporate after application to leave the remaining material similar in hardness to the original bitumen. Normal practice is to heat bitumen to reduce its viscosity. In some situations, preference is given to use liquid binders such as cutback bitumen. In cutback bitumen suitable solvent is used to lower the viscosity of the bitumen. The solvent from the bituminous material will evaporate and the bitumen will bind the aggregate. Cutback bitumen is used for cold weather bituminous road construction and maintenance. The distillates used for preparation of cutback bitumen are naphtha, kerosene, diesel oil, and furnace oil. There are different types of cutback bitumen like rapid curing (RC), medium curing (MC), and slow curing (SC). RC is recommended for surface dressing and patchwork. MC is recommended for premix with less quantity of fine aggregates. SC is used for premix with appreciable quantity of fine aggregates.

Related Products

- • Cutback Bitumen Rapid Curing (RC)

- • Cutback Bitumen Medium Curing (MC)

- • Cutback Bitumen Slow Curing (SC)

Environmental Comparison of Cutback Bitumen and Bitumen Emulsions (for Sealing Roads)

A recent environmental research project compared the environmental impacts of bitumen emulsion to cutback bitumen, based on Fulton Hogan production and usage data. In addition to the health and safety, and technical benefits of bitumen emulsions, the research project found that:

1. Greenhouse gas emissions from the use of cutback bitumen are significantly higher than for bitumen emulsions due to the large amount of fossil fuels used for heating cutback bitumen and through the evaporation of kerosene from cutback bitumen chip seals;

2. The increased transportation emissions associated with bitumen emulsion are not significant when compared with the production and heating emissions for Fulton Hogan’s chip sealing operations;

3. Replacing cutbacks bitumen with bitumen emulsions would reduce the amount of CO2 produced from sealing operations by almost two thirds;

4. Replacing cutbacks with emulsions would also reduce production of photochemical smog generating VOC emissions to atmosphere.

Source: The National Academies of Sciences, Engineering, and Medicine